Projects > Mackay sports precinct

Hanceys turf has gained a reputation for building high quality sports surfaces of all types in South east Queensland but were invited as the preferred contractor to build an athletics infield and multi purpose facility up in Mackay. Having worked successfully with Track specialists, Polytan, at both Runaway bay sports super centre (Gold Coast) and Sheldon college (Brisbane) in recent years, Paynter Dixon, the principal contractor for the Mackay regional council’s new sports precinct had no hesitation when it came to selecting two contractors to build an artificial athletics track and grass infield.

Previously the site of a sugar Cane farm, in Oralea, Mackay, the local council decided to build a rubber crumb running track surrounding a natural turf athletics infield, also to be used for rugby union, league and soccer, as a facility serving both the local community and Central Queensland university whose campus is next door. Significant investment had been gained through state and local council funding meaning a $24 million dollar facility could be built including the running track and infield, 2 Olympic sized pools, a junior pool as well as changing rooms, restaurants, clubhouses and car parking.

The contract for Hanceys turf specified the design and construction of a playing surface that could handle the general climate, heat and humidity of North Queensland as well as the tropical storms that can effect the area, non more obvious than the deluge suffered recently in Townsville just a few hours north. Nathan Hancey and project manager Mark Patterson designed a field capable of handling such climatic extremes which included drainage, irrigation connected to a new bore pump and controller, a 200mm layer of amended rootzone sat over a indigenous clay sub base and turfed with washed wintergreen couch grass. These plans were submitted to an independent consultant for evaluation, Matt Roche from the ASTC, who then added his own advise on amendments and drainage spacing before work commenced in May 2018.

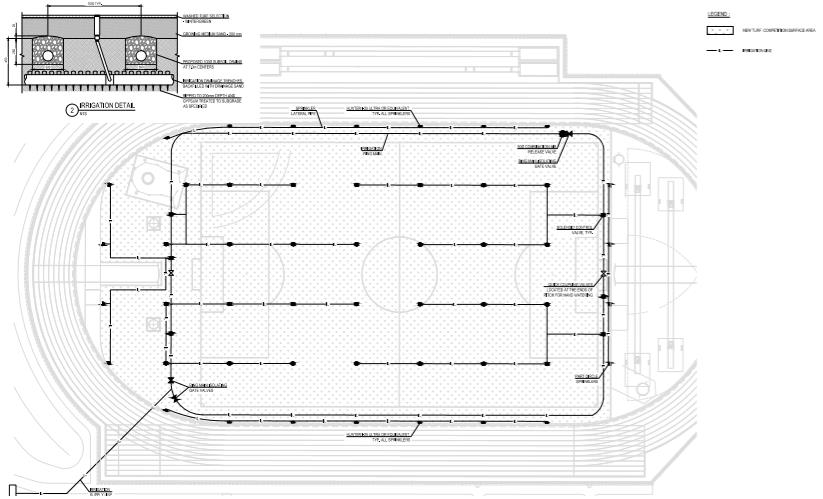

Hanceys arrived onsite mid May and had been handed a sub grade by the civil contractors which was 200mm below finished height, shaped at 0.5% falls from centre to touchline. The first job on the specification was to rip and amend the subgrade with Gypsum and lime to aide root growth and drainage, before laser grading with falls to +/- 10mm. Once this was completed we could now begin installing the new irrigation system. Pipes were trenched in at 400mm below subgrade height to allow for the drainage pipes to cross over and above them at numerous points. Once fully installed and connected, the elbows where sprinkler heads would screw on were instead capped to avoid damage or crushed during the next phase of works. GPS plotting these locations proved to save a lot of time (and digging) at a later stage. All piping was sand back filled, for protection of the pipes and ease of any future maintenance requirements.

To complete the irrigation component of works and connect pipework to the new bore pump, the slightly complicated task of trenching under and across the track was necessary but completed on schedule and worked in well with Polytan’s program of track works. Relatively simple jobs included flushing and testing the system as well as GPS plotting each sprinkler point, solenoid valve and two stop valves were completed and the sub soil drainage could begin. The field was then graded again at this stage to remove any spoil from irrigation trenching and ensure the subgrade was perfect again before drainage trenching began.

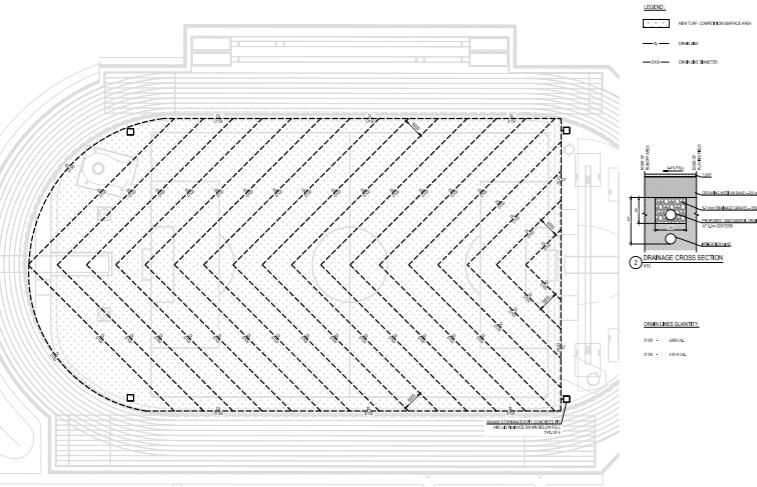

The Mackay council had only specified one part of the field build (the rest being entirely left to Hanceys knowledge and expertise) and that was requiring the field be as flat as possible as it was predominantly to be an athletics infield. This meant that the drainage design involved calculations based on required drainage rates versus a fall of only 0.5% (as opposed to the usual sportsfield build of 1% falls.). It was decided therefore that drainage spacing be at 5m centres using 100mm agi pipe falling into a 150mm collector pipe around the field perimeter. These 150mm collector drains then feed into four stormwater pits at each corner of the field, and away offsite into the local water courses. Also, a drainage system was designed that resembled one large herringbone, as opposed to the normal grid system drainage designed by Hanceys turf on other sports fields; implemented to catch as much rainfall as possible in the most efficient way.

After a rain delay, (drainage earthworks should only ever take place in dry conditions!), The Marking out and general set up began, and all laser trenching, back filling and tidy up was completed in just under a week using sportsturf specific machinery, possi tracks and small two tonne trucks to remove spoil. Because all the machinery was so lightweight and purpose built for sportsturf, the subgrade was relatively undisturbed by works, this being imperative if the drainage design was maximise its potential and maintain a 160mm per hr percolation rate.

With this stage of works complete importing of the rootzone layer could begin. Hanceys turf sourced the sand material from the ‘Mackay sand and gravel’ company’s quarry in North Mackay. Having looked at several options for this key component of the build, Mark P chose to use local products after inspecting and testing the sand for various reasons; Firstly: cost – obviously trucking materials from our regular suppliers in Brisbane would prove far too expensive and exceed the clients budget, secondly: quality – after samples were taken and sent to Groundscience labs in Melbourne, results showed a high quality, consistent and clean material which reached both percolation rate requirements and moisture retention ability due to correct particle size distribution. Matt Roche, the turf consultant, added his amendment recommendations to provide a great growing medium for the turf, (various amendments were added to what was essentially a raw product including calcium for salt reduction, amendmax to add organic content and wetting agents). Thirdly: using a local product meant that our client could easily and cost effectively source the exact same material in future for top dressing and maintenance as and when it is required. Mixing of materials is never recommended by Hanceys as it can create a layering effect throughout the rootzone).

The Importing of the rootzone material began in early August, some 2500 tonnes required to build the 200mm layer. Truck and dogs obviously couldn’t drive on the subgrade as this would cause unwanted compaction and/or damage the drainage so material was dropped on the edge of the field in two corners left accessible by the running track contractor. From here a D6 Drott (set on the correct finished levels using a total station) created a pad and pushed the sand out, also pushing material was one of Hanceys various large turf tractors.

This technique, whilst slightly more time consuming, means that the drainage remains completely intact and compaction and contaminant free once the sand material is pushed out on top.

Once the amendments had been added and worked in two directions with Hanceys turf Blecavator’ a smaller laser bucket grader was used to final trim the field on +/-5mm before turfing.

The sprinkler heads could now be added and set on finished height, with a final testing of the system running through several irrigation programs before turf harvesting began. Adding moisture to the ground at this stage holds the graded sand material in place as well as flushing any salt out of the sand profile. Further Calcium was added to the surface at this stage to ensure the salt percolated through into the subgrade and drainage, as well as a good balanced turf starter fertiliser NPK 20:10:10, and Oxamax pre-emergent to stop unwanted weeds germinating.

The turf selected for the field was Wintergreen couch grass grown at Hanceys farm at Woodford on one of its sand based paddocks so as to marry in with the profile onsite. Washing the turf was still necessary to remove any unwanted silt or clay from the sods to ensure the rootzone had absolutely no contamination. Trucking the turf from South east Brisbane to Mackay was a slight concern, however using trucks with full tarpaulin sides minimised wind burn and stopped the turf drying out, and also good project management meant early September was the perfect time of year to transport and lay the turf, temperatures relatively low but still spring was just around the corner for turf establishment and early maintenance. Turf works were completed within 4 days, including fertilising, a final roll and initial watering requirements now programmed in.

A 10 week maintenance schedule then began, as is general practice to ensure the turf is fully established, healthy and measuring strong deep root growth. This involved regular maintenance practices such as mowing, cross rolling, fertilising, aeration, weed and pesticide treatments if necessary and a final top dressing of the field so that the client was handed over a field in perfect condition and ready for play.

The project was completed on schedule and within the budgets allocated. Mackay regional coucil are so impressed they have asked Hanceys Turf to remain involved as sportsturf consultants for all future works, they now own a very high standard sportsfield to complement its surrounding in the new Sports precinct, which if managed correctly will play well and more than pay for itself for years to come.