Projects > North Pine Christian College

Scope

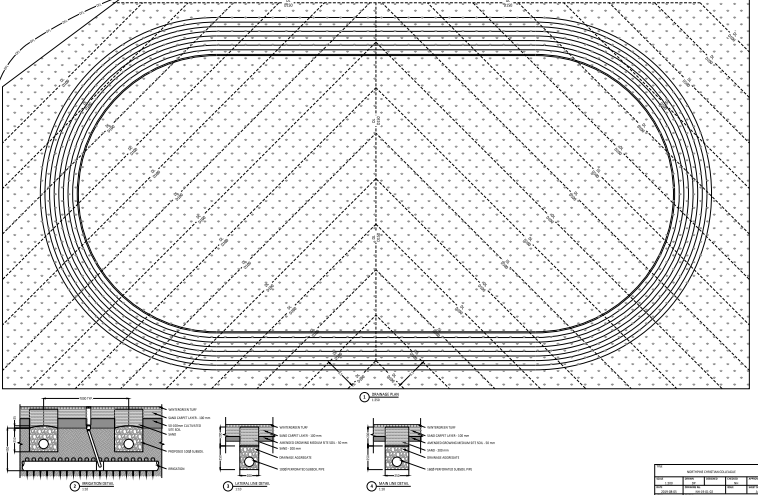

Hanceys Turf was approached by the college to design and rebuild a new oval for the school. The oval was to be a multiuse area to include a 400m Athletics running track, full size AFL field, and 2 soccer fields. The design was to improve useable hrs so it could be used after rainfall as the previous field was also sodden and pooled water on the surface. The design was to also make full use of the Irrigation dam to the North so we made all the drainage and grades fall to the dam to catch and re- cycle 100% of the run off and excess rainfall. A sub surface drainage system w as also installed, an new irrigation system and a 100m layer of amended USGA Turf sand. The turf selection was Wintergreen Couch.

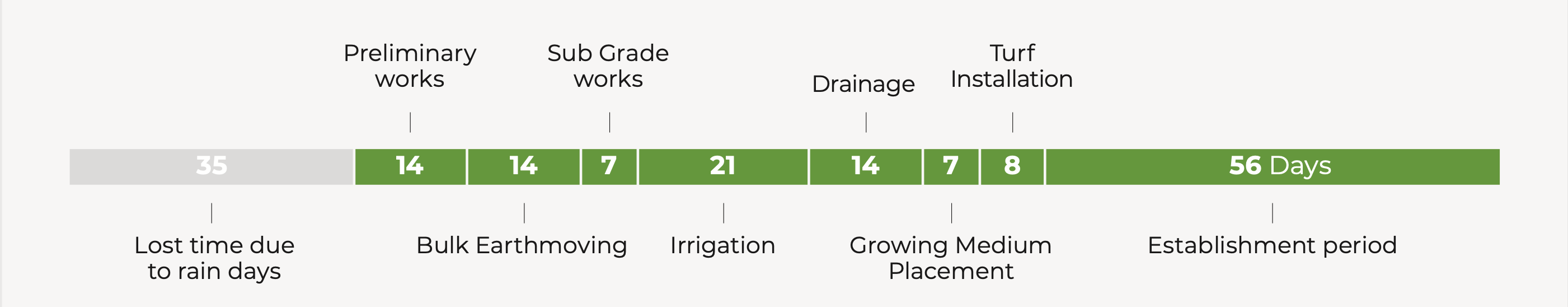

Timeframe

The works started in October 2019 and after all the construction process the turf was installed in February 2020. The establishment period was 8 weeks and the hand over was on April 2020.

The project took approximately the following:

Bulk Earthmoving

Due to the large amount of cut and fill required (9,000m3 over 25,000m2) we used large tractors and laser buckets which quickly cut, load, haul and fill all in a single pass. These machines are all on GPS machine control to minimise human error and maximise accuracy and precision especially when a few machines are operating on the same site.

Due to the Q100 level and also the current existing services already in place we needed to design the field layouts to best suit the lay of the land within these restrictions. Surveying and creating a designed model to facilitate this was vital to get the desired result we needed.

Sub Grade Prep

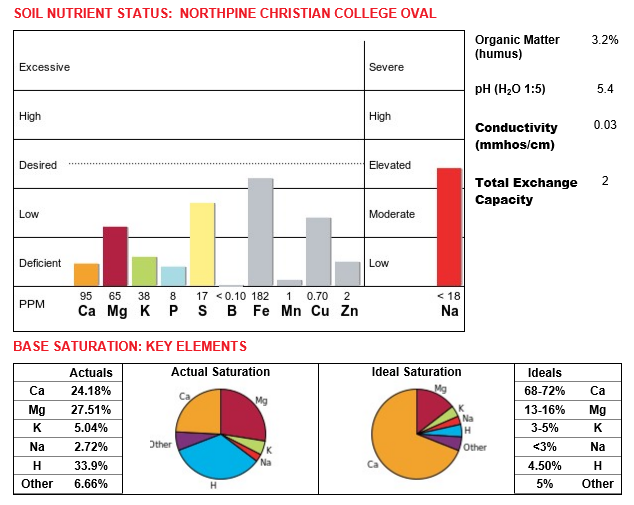

Due to the sub grade only being 100mm below the top surface we treated it like a base growing medium, we have the soil tested and amended is mirroring the finished surface but 120 mm below (100mm of amended USGA Sand and 20mm of turf) The sub grade was ripped, incorporated with organics, lime and gypsum (Calcium) as well as magnesium, phosphorus and potassium. The amendments cultivated in and then consolidated ready for the next step.

Irrigation

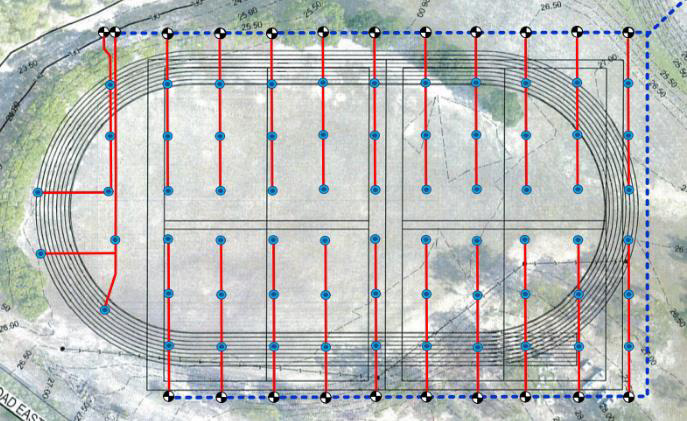

A irrigation system was designed and installed. The pipework had to be installed underneath the drainage system. The new irrigation pump proposed also needed to have large capacity to handle an old irrigation system, the new oval as well as future proposed projects.

The total system designed had:

- Hunter Hydrawise Wifi Controller system

- Hydrovar Irrigation pump

- Automatic filtration system

- Hunter Irrigation Heads to keep the heads uniform as used throughout the rest of the school

- 4 QCV Valves in each quadrant of the perimeter

- 90mm Mainline

- Shut off Valves in mainline for future works

Drainage

The drainage system was designed to extract maximum cross fall of infiltrated water while also falling towards the dam catchment area to re-cycle the drainage water.

The system installed has:

- 2,900 lineal mtrs of pipe work and trenching etc

- 8.5m spaced 100mm lateral lines

- 150mm Ring main and Centre Main Line

- The perforated sub surface 100mm and 150mm pipe used are both premium double wall smooth bore pipe

- Drainage material used was 5-7mm washed gravel and washed drainage infiltration sand

The 100mm Growing medium is also an amended USGA Turf sand specifically blended for the required drainage infiltration rates while also having nutrient and correct moisture retention for producing a quality playing surface. All trenches where consolidation to minimise compaction losses prior to placement of growing medium.

Growing Medium / Sand Carpet Layer

A USGA sport turf sand blended with amendments for nutrient holding and moisture retention was selected for the best profile for the top 100mm for a quality rootzone for vigorous turf as well as enough infiltration for surface playability after rainfall. The final surface is on a single grade of 1.2% fall all towards the irrigation dam on the North.

The 4000 tonnes was tipped on 2 faces each side of the field and pushed out over itself with a drott with our medium sized laser bucket trimming the sand to 7mm tolerance on grade. We do this method so no trucks and machinery can damage the integrity of the drainage system, irrigation system and sub grade.

Turf Production

A Paddock of Wintergreen was selected for Grow in on this project and was intensely managed for 6 months on a program of:

- Mowing- twice a week at 20mm with a cylinder mower

- Pre-emergence program every 12 weeks

- Fertiliser program granular (6 wks) and liquid (bi-weekly), nutrients applied were dictated by soil and leaf analysis

- Accelepryn pest applications every 8 weeks and 1 week prior to harvest

- Banner Maxx fungicide 2 applications made 6 weeks apart

- Post Weed control 4 weeks prior to harvest with Monument and Bow and Arrow.

The paddock selected for this turf mirrored the final location of the sports field. The fall on the production pad was 1.2% and it has pop up automated irrigation the only variation being it was produced on a loam growing material.

Turf Installation

Turf installation was done with an average of 3,000m2 per day, We would harvest at 2 to 4 am in the morning, have turf onsite at 7am and all turf would be harvest, transported and installed within a 12 hr window.

Our method for the turf install is that we have purpose turf haul out tractors fitted with floatation tyres so the prepared surface has minimal damage. We do not let the truck forklifts on the prepared ground. Another important note is we always install inline with the irrigation system stations so we can section turf off daily and give it a light drink overnight without flooding the next area.

Once the turf is installed, we roll, apply a starter fertiliser, apply Ronstar pre emergence and set a irrigation program for 2 weeks of daily syringe watering. This watering program will keep the turf roots moist. Once the turf has taken root we start and reduce the irrigation program back.

8 week Establishment period

After the turf has taken root we gave it its first mow, we double cut it and vacuumed the clip just to maintain a open sward, minimise the thatch and manage any risk of disease as we had been getting weekly substantial rainfall.

Esteblishment includes:

- Rolling

- Mowing program

- Top dressing 10mm USGA Turf Sand • Disease, weed and pest control

- Fertiliser program

- Irrigation management