Projects > Sheldon college field build

Hanceys turf worked successfully with Polytan at Runaway bay sports super centre two years ago so when consultant Bob Jones came to select two contractors to build an artificial athletics track and grass infield he had no hesitation in employing the same two companies again. Previously a grass running track and AFL oval, Sheldon college decided to build a rubber crumb running track surrounding a natural turf infield to be used for rugby union, league and soccer.

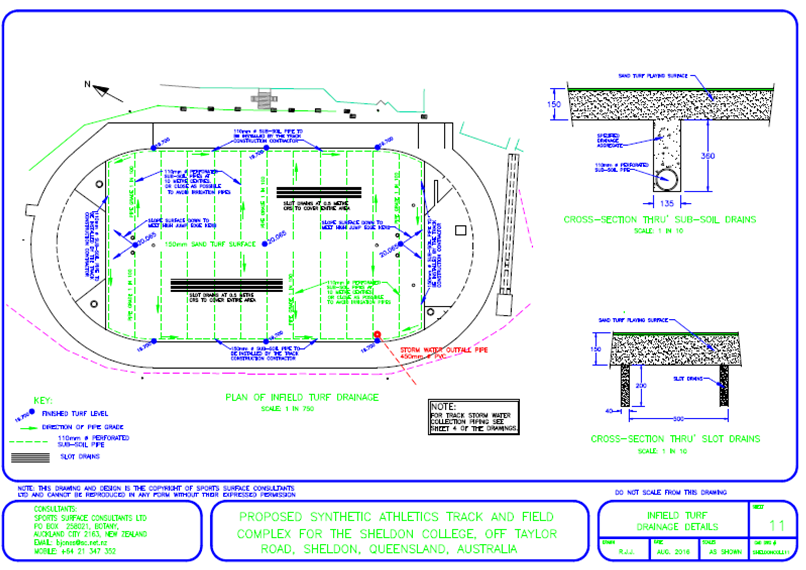

The consultant’s specifications were to remove 200mm of existing site soil, level this new subgrade, install a new irrigation system connected to the old main inlet and pump system. The drainage system specified for 100mm agi pipes in trenches at 300mm below finished subgrade heights east to west across the field and topped up to subgrade level with 5mm gravel all on a 1% fall to an outer 150mm ring main drain. Hanceys then installed gravel bands North to south along the field 500mm apart at a depth of 200mm to connect all the sub surface drains, using Hanceys Koro top drain gravel/sand banding machine. This machine can be set at various depths to a maximum of 250mm, creates 50mm wide slits, removes spoil and back fills with specified material and compacts the trench all in one pass, 3 trenches at a time.

With this stage of works complete importing of the rootzone layer could begin. Truck and dogs brought the 3000tonnes of pro2 blend sand material from the Riversands quarry at Carbrook but they obviously couldn’t drive on the subgrade and damage the drainage so dropped material on the edge of the field where a D6 Drott (set on the correct levels using a total station) created a pad and pushed the sand out from there. A possi track bobcat with laser levelling blade was then used to final trim the field before turfing.

The turf selected for the field was Wintergreen couch grass grown at Hanceys farm at Woodford on one of its sand based paddocks so as to marry in with the profile onsite. Washing the turf was not necessary then (as is usually the case when building a high specification field) meaning a large cost saving to the client. All works were completed within a 4 week window and again a 10 week maintenance schedule began.

Both fields are Have now been handed back to the clients on schedule and within the budgets allocated. These two very different projects have offered different solutions with the same outcome; a very high standard sportsfield which if managed correctly will play well for years to come. For more information please contact Nathan or Mark at Hanceys turf.